Biological control and quails

Hartog Palmen uses biological control in its cultivation process. For example, the various pests are controlled using small insects and nematodes.

There are also quite a few quails running around the nursery, which take care of eating away weeds and pests.

Yellow glue boards with pheromones

You will also see many sticky ‘yellow glue boards’ hanging throughout the greenhouse. Attached to these cards is a pheromone capsule. From these, a species-specific sex pheromone (attractant) is released that lures adult males of the pest species in question ‘into the trap’. There, they stick to the glue plate and are thus easy to observe, count and identify. We thus ‘trap’ moths in a biological way.

Catch lights

We also catch moths with catch lights. Among other things, the insect lamp emits UV light. UV cannot be detected by humans. For insects it is. They are attracted to UV light. The coating in the lamp, in combination with UV and organic matter, produces a slight increase in CO2 compared to the environment. This is attractive to insects. The virtually silent fan sucks the insects into the collection tray. Two check valves prevent them from escaping. The air flow from the fan dries out the trapped insects.

The catch lights are on only at night, as moths only fly at night.

Energy / WKK

Hartog Palmen uses energy very efficiently. The natural gas, which used to be burned in the boiler, now goes into a combined heat and power plant (WKK). This is a small power plant that can produce 0.9 megawatts of electricity.

The greenhouse is heated with heat generated in the CHP. The electricity generated during this process is supplied to the utility company that supplies the Netherlands.

Did you know that over 15% of all electricity needed in the Netherlands is generated by the horticultural sector?

Dehumidifiers

Hartog Palmen uses six dehumidifiers in the greenhouse from Drygair. These devices remove excess moisture from the air, reducing the risk of mould forming in the plant. The investment also contributes to more sustainable operations. Indeed, by dehumidifying in the greenhouse, the windows need to be opened much less often. When windows are opened, a lot of heat and CO2 is lost. So leaving the windows closed as much as possible saves a lot of energy.

Screen cloth

The greenhouse is equipped with double screen cloths. The upper screen consists of two cloths lying on top of each other, which have a darkening effect and insulate very well. The lower screen cloth provides extra insulation and is 100% diffuse. This ensures that the light entering the greenhouse is optimally distributed over the palms. As a result, there are no shadow paths in the greenhouse and every plant can get the same amount of light.

The insulation is so good that it can freeze above the cloth when it is very cold outside and still keep the greenhouse at a good temperature under the cloth.

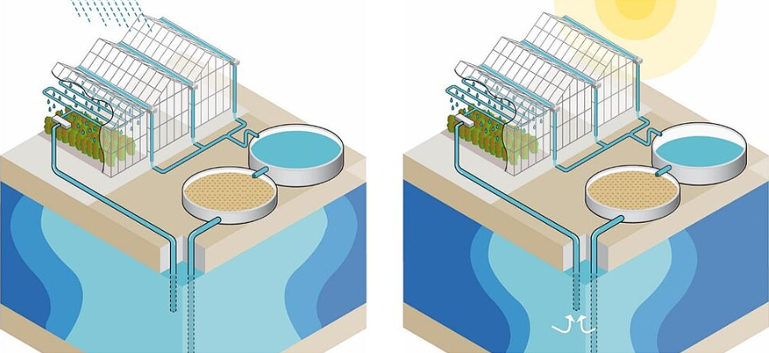

Water storage in basins and storage of water in the ground

We have several above-ground basins outside to store rainwater. However, we also use underground rainwater storage. This way, a much larger amount of water can be stored and no additional area is needed on site for storage in basins. Underground storage of rainwater can help ensure good quality water is always available in an economical way. Over an entire year, enough rain falls to water crops, but rainwater is not always there when it is needed. In spring and summer the rainfall is low and in the rainy season there can be a surplus. At Hartog Palmen, we mainly use the water from the soil storage for the high-pressure mist system. Rainwater is good quality and free. Nor do we use water from the ‘tap’.

How does water storage in soil work? To infiltrate water into the soil, a suitable soil layer is needed. Below the clay layer of 10 to 20 m, there is usually a suitable sand layer at a depth of 20 to 50 m in the western Netherlands. There is a third space in the soil between the sand grains, which can be used for underground water storage. In the sand layer are one or more pipes with holes. The holes act as a filter, through which water can pass but not sand (grains).

To retain rainwater briefly, it is first stored in the existing water basin or silo. From the intermediate storage, the water first passes through a sand filter, after which it runs into the ground from a three-metre-high tube under the influence of natural gravity.

Disinfector

All water used in the greenhouse is disinfected with Ozone. Ozone (O3) enables optimum reuse of water. The natural gas Ozone falls back to oxygen after treatment. Oxygen-rich water for cultivation! Agrozone’s disinfector allows us to reuse our water. Water quality improves with the least possible consumption of energy, fertilisers and water. Ozone is very suitable for this. By disinfecting with Ozone, no harmful substances need to be used.

Sprinkling and watering

Concrete floors

The greenhouse is fully equipped with a concrete floor, creating the most hygienic conditions and preventing mould growth. Also, the water that drains away from watering the plants can be optimally collected and reused after disinfection.

Ebb and flow system

We use an ebb and flow system on the concrete floor to irrigate the plants. An ebb and flow system allows the floor to be flooded in different sections of the greenhouse at different heights. The water, complete with fertilisers, emerges from the floor and, after some time, drains again. That water is collected and disinfected again. The germs are taken out and also the remaining fertilisers. Previously, that water ran back into the ground, so now this has become a circular process. By watering from the floor and not just by sprinkling, the risk of mould in the crop is reduced.

Water from above

We most often still ‘just’ water from above. This keeps the plant fresh and clean. This water is also collected, disinfected and 100% recirculated.